Optimized production with new dehumidification system

Lactosan produces cheese powder for the food industry, and this is done through a drying process that uses the outdoor air as a medium. However, as the temperature and humidity of the outdoor air vary throughout the year, Lactosan’s production has been greatly affected by the changing quality of the outdoor air.

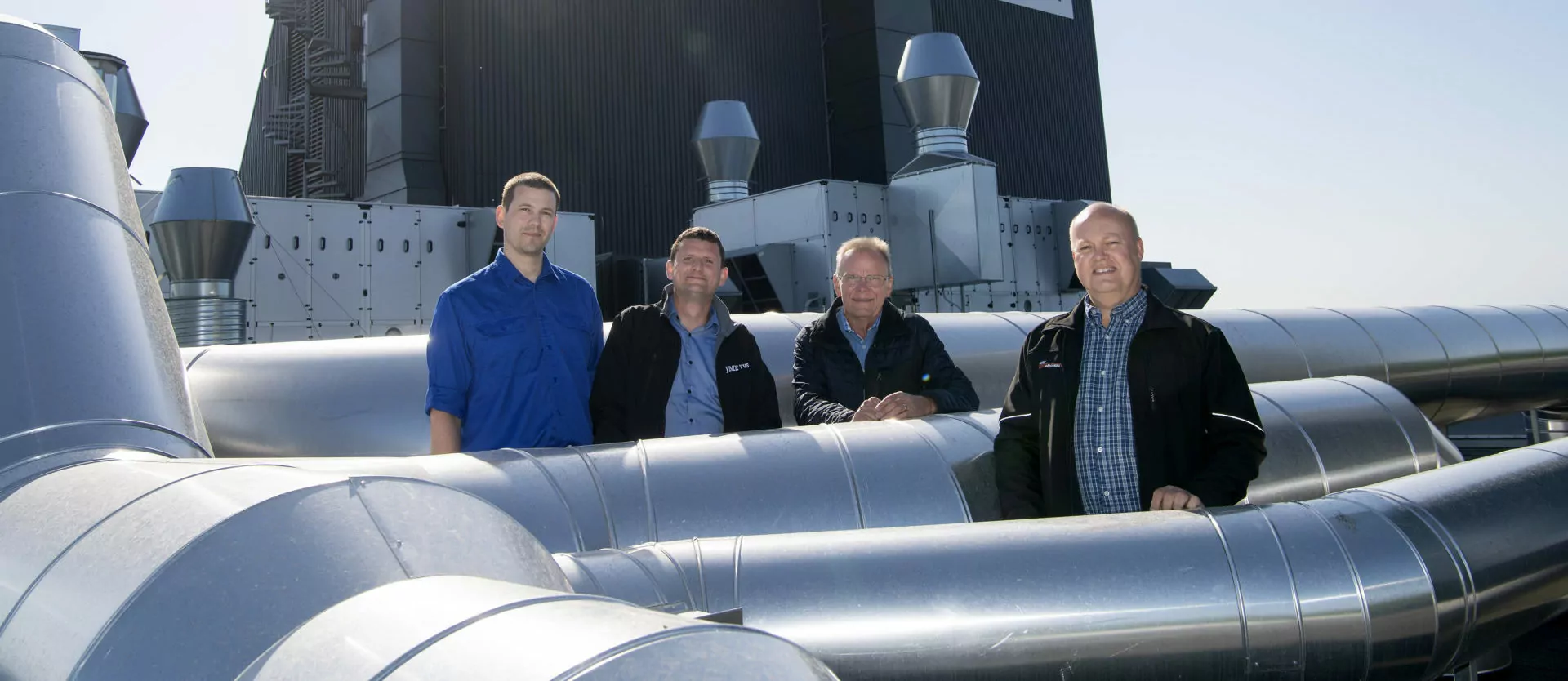

To address the problem of the changing quality of the outdoor air, Lactosan has now established a dehumidification solution.

The new dehumidification solution has given Lactosan a higher and more stable production and at the same time saves energy.

The dehumidifier helps us to standardize the quality of the air we use in the drying process. Now a fully automatic process is running, which ensures that the drying process is supplied with the desired amount of air at a certain temperature and humidity. In this way, we have eliminated an uncertainty factor that has affected our production in the wrong direction. With the dehumidifier, our production has now increased and we use less energy for the same production.

Jan Nykjær Pedersen, engineer and technical manager, Lactosan

The calculated gain was an energy saving of 10-15 percent, in addition to the fact that Lactosan in the summer months with more humid outdoor air will be able to maintain a higher, more stable production, because the dehumidification solution keeps the humidity down to the desired level.